Juliano's

Early Ford Top Kit

How-to

by Bob Juliano

HOW TO: INSTALL

A TOP KIT INSERT

A Kit for the home builder

|

| One of the few

areas left in street rod building that the home builder doesnt venture

into is the upholstery portion of the car. Bob Juliano brought this to

our attention several months ago, and agreed to do a series of articles

on how this job can be done at home. Since Bob operates a trim shop, it

was only natural that he offer a kit for the backyard builder. If your

rod is ready for a top insert, follow along as Bob installes a new

insert on a chopped deuce Vickey. |

|

1) First step is to remove all the old chicken wire and

matting. Use care in removing the staples.

2)Check the wood for warpage or rotting and repair as

needed

|

| The first step in

installing a new top insert is to remove all the old material from the

top. This includes the chicken wire and matting. After that is removed,

check the wood to insure that it is in good condition. If the wood is

dry rotted, or cracked, make sure that they are uniform in height. A

long straight edge works well for this portion of the job. After the

wood has been repaired or replaced, it is time to get on with the job

of covering the insert. |

|

3)Check the top bows with a long straight edge

to insure that the bows are uniform in height. |

| Now take the

aluminum track that is supplied in the kit, and drill 1/8" holes, every

two inches. A wood block should be used for back up, and care must be

taken not to bend the track. After drilling, deburring all holes, to

insure a tight fit to the roof. |

|

4) Drill a 1/8" hole every 2 inches in the

aluminum track supplied in the kit. Be careful not to bend the soft

track, and debur all holes. |

| Now that the track

is drilled, it is ready to be formed. Start on a straight portion of

the roof, 1/4 to 1/2 inch outsid the original to insert. Drill the

first hole through the track, into the roof and pop-rivet the track to

the roof. Aluminum pop-rivets are used for this. Continue this process,

forming the track to the shape of your top insert. Once the track is

formed and riveted every two inches, new holes must be drilled between

the rivets creating holes through the track and into the roof every

inch. Do not waste rivets in these holes, as the track must be removed,

however it is necessary to have provisions for rivets every inch for

the finished job. |

|

5)Pop-rivet the track to the roof approximately

1/2 inch from the original tack strip. |

| Using a 1/8" drill

remove the rivets by drilling the heads out. Remove the track taking

care to mark left, right, front, and back. The track is now ready for

the final installation. Carefully set the tracks aside. |

|

6)Form the track as you go. A friend or wife to

help will make the job easier. |

| The next procedure

is to prepare the vinyl covering for installation. We have discovered

the best way to assure a smooth, tight fitting top is to fasten the

vinyl to a stretcher frame, constructed of 2" by 3" boards. This frame

should be approximately 2" smaller than the vinyl supplied in the kit.

Staple the vinyl to the frame stretching tightly as you go. For best

results the vinyl should be warm. This can be achieved by working in

the sun or by using a heat lamp. When stapling the vinyl to the frame,

in a manner so as to avoid the frame coming in contact with the body.

After the vinyl is stretched, place it and the frame aside.

|

|

7) After building a stretcher frame form 2 x 3

wood, stretch the vinyl over the frame. The wood frame should be placed

on the finished side of the vinyl. |

| The next step is to

prepare a base for the padding. We have found that a special canvas

works better than the original chicken wire. This special canvas

(supplied in the kit) stretches taut and will not let air through it,

this eliminating the possibility of the top balooning up as you drive

down the road. The canvas staples to the same place the chicken wire

was stapled in the original application. Stretch the canvas tightly as

you go, and staple it to the outer tack strip. A few staples are used

across the bows for extra protection. Trim the canvas with a razor

blade or scissors. Trim very close to the staples. |

|

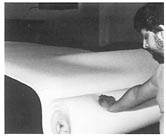

8) Staple the special canvas to the tack strip,

stretching it tight as you go. |

| Now that the base

is installed it is time to install the foam padding. Spray contact

cement is used to hold the foam in place. Use a couple of awls or

punches to locate the holes. Then run a razor blade along the inside

edge of the track. Special care must be taken to insure that no foam is

under the track. |

|

9) Now trim the canvas close to the staples with

scissors or razor blade. |

| Now that the foam

has been trimmed the vinyl material is ready to be installed. The vinyl

supplied in the kit is a high quality vinyl that is completely

waterproof. Place the wood frame with the vinyl attached to it on the

roof. Carefully center the vinyl on the roof. |

|

10) Lightly spray contact cement on the canvas,

and roll out the foam padding. |

| With the vinyl

centered on the roof, re-install the aluminum track. It is very

important to make sure the track is in the correct position before

riviting. Use an awl to aid in this process. Once the first pop rivet

is inserted, continue riviting every inch until finished. Do not skip

any holes. After all the rivets have been installed, cut the material

leaving approximately 6" of excess and remove the frame from the roof.

Using a razor blade, trim the vinyl close to the outside edge of the

aluminum track. It is important not to cut into the paint or primer

during this process. |

|

11)Trim the foam to the inside edge of the

track. Care must be taken not to allow any foam to protrude under the

track. |

| All that is left

now is the final trim that snaps on the aluminum track. Install this

finish moulding from the kit, starting at the center rear of the roof,

carefully cut the moulding. A good clean, straight cut here will make

the seam unnoticeable. After checking the fit of the seam, lift up two

inches on either side of the seam, and apply a light coat of contact

cement to either side of the splice. Now re-snap the moulding, making

sure that the seam is aligned properly. The glue will help to keep the

seam tight during the expansion or contraction due to changes in

temperature. |

|

12)Place the vinyl and frame on the roof of ot

the car, and center it. |

| All that is left

now is the final trim that snaps on the aluminum track. Install this

finish moulding from the kit, starting at the center rear of the roof,

carefully cut the moulding. A good clean, straight cut here will make

the seam unnoticeable. After checking the fit of the seam, lift up two

inches on either side of the seam, and apply a light coat of contact

cement to either side of the splice. Now re-snap the moulding, making

sure that the seam is aligned properly. The glue will help to keep the

seam tight during the expansion or contraction due to changes in

temperature. |

|

13) Re-install the aluminum track with aluminum

pop-rivets. Dont skip any goles and be sure that you have a rivet every

inch apart throughout the complete track. |

| After checking the

fit of the seam, lift up two inches on either side of the seam, and

apply a light coat of contact cement to either side of the splice. Now

re-snap the moulding, making sure that the seam is aligned properly.

The glue will help to keep the seam tight during the expansion or

contraction due to changes in temperature. |

|

14)Now trim the canvas about 6 in. from the

track. Be careful not to hit finished paint or body work with the

scissors or razor blade. |

| All that is left

now is the final trim that snaps on the aluminum track. Install this

finish moulding from the kit, starting at the center rear of the roof,

carefully cut the moulding. A good clean, straight cut here will make

the seam unnoticeable. After checking the fit of the seam, lift up two

inches on either side of the seam, and apply a light coat of contact

cement to either side of the splice. Now re-snap the moulding, making

sure that the seam is aligned properly. The glue will help to keep the

seam tight during the expansion or contraction due to changes in

temperature. |

|

15)Using a razor, carefully trim the vinyl very

close to the track. Hold the excess material up and away from the track

to aid in this process. |

| So there you have

it, a top quaility kit for the backyard builder. |

|

16)The vinyl molding is snapped in place. The

final seam is carefully cut, and glued in place. The seam should be at

the center rear of the roof. |

|