![]()

Step 1

These are all the parts included with

the Juliano's seat belt kit. Take some

time to familiarize yourself with the

parts as well as the instructions.

|

![]()

Step 2

Measure up from the floor to locate

the shoulder point. This location can

vary do to seat high and passenger

size so be sure to factor this in.

|

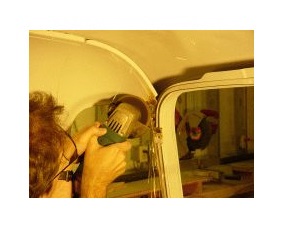

![]()

Step 3

Make up a template for the area

as shown that will fit down behind

the sheet metal.

|

![]()

Step 4

Clamp the template behind the

sheet metal and drill an 1/8" hole

at your shoulder point mark, being sure

to drill through the metal and template.

|

Step 5

Align the holes on your template

and fine tune it to clear any

interior panel screws or other

obstructions.

|

Step 6

Trace your template onto the

included B-pillar bracket, being

sure to align the hole with the

threaded shoulder bolt hole.

|

Step 7

Grind or cut the B-pillar

bracket to match your template.

|

Step 8

B-pillar bracket ready for

installation.

|

Step 9

Test fit the bracket and be sure

that the pilot holes are aligned.

Now drill the 7/16" hole for the

shoulder bolt.

|

Step 10

Drill two more holes, one above

and one below, to spot weld the

bracket in place.

|

Step 11

You may have to bent the bracket

slightly to match the contour of

the cab.

|

Step 12

Re-install the bracket and use the

shoulder bolt to tighten in place.

You can also use a clamp to hold

pressure on the plate while welding.

|

Step 13

Spot weld the bracket in place

using the 2 predrilled holes.

|

Step 14

Clean up the welds. 120 grit

flapper wheel on a 4" grinder works

well for this.

|

Step 15

Here is the retractor installed.

This location will keep the retractor

mechanism clear of the fuel tank,

filler neck and cab mount.

|

Step 16

Place one of the 90 degree

L-Brackets supplied on the cab

floor behind the seat pedestal as

shown to layout mounting hole.

|

Step 17

Drill the 7/16" mounting hole.

|

Step 18

Next layout one of the included

anchor plates to match the contour

of the cab.

|

Step 19

Trim the plate and mock up to be sure

hole lines up. Adjust as needed.

|

Step 20

Bolt the plate in place using one of

the included bolts. Weld the plate to

the seat pedestal.

|

Step 21

Install the L-Bracket and bolt in place

using one of the lock nuts. The bracket

should sit flat on the floor and the corner

should just touch the small support.

|

Step 22

Weld the L-bracket to the floor and

support beam.

|

Step 23

Here is the finished mounting plate.

|

Step 24

Mount the retractor by using one of

the 1-1/2" long bolts and washer

through the front and tighten. Install

the retractor and tighten lock nut.

|

Step 25

Install the shoulder point using the

included shoulder bolt.

|

Step 26

Layout the mounting points for the

inboard soft arms. Typical spacing

between the retractor and arm would

be between 15" and 25".

|

Step 27

The holes should be just far enough

in front of the seat pedestal to provide

clearance for the end fitting to clear

the pedestal.

|

Step 28

You may need to adjust the

placement of the plate a little to

provide a flat surface for mounting.

|

Step 29

Drill the 7/16" mounting holes. Also

drill 2 holes to spot weld plates in

place, one just behind the riser and one

just in front of mounting hole.

|

Step 30

Bolt the plates in place under the

truck using supplied bolts.

|

Step 31

Spot weld the 2 plates in place.

|

Step 32

Clean up the welds using a 4"

grinder with 120 grit flap disc.

|

Step 33

Bolt the inboard arms in using supplied

1-1/2" long bolts and flat washers.

|

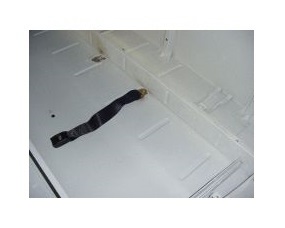

Step 34

Inboard arm installed.

|

Step 35

Time to enjoy your ride and be safe!

|

|